Our Facility

Our Fosdick direct dial automatic positioning jig bore is one of the largest in Central New York. It has a 22″ X 54″ table, enabling us to handle parts up to 4′ X7′. Other Advantages of the jig bore include:

spindle to column 24″

spindle to column 24″

spindle to table 24″

capability of maintaining true position tolerance of .0002″

This Matsuura 760V vertical machining center offers a wide range of capabilities. It is CNC-controlled with 30″ X, 16″ Y and 19″ Z axes. This machining center is ideal for processing precision components for the aircraft, electronic and nuclear industries. Its advantages are:

spindle speed 4500 rpm

spindle speed 4500 rpm

10 HP motor

30-procket automatic tool changer

ability to quickly and easily cut through hard-to-work materials such as stainless and inconel

capability of maintaining true position tolerance of better than .0005″

Kemsley Machinery Co., Inc.

This is our Check Master 20 X 20 X 15 Coordinate Measuring Machine

Dimension check to .0001″

Angle check to .001 Degrees

Calibrated and traceable to the National Bureau of Standards

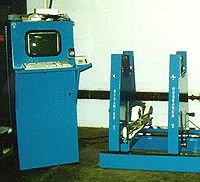

The Dynamics Research Balancing Machine Model 605 uses a computer and analog to digital conversion system to gather data and perform the mathematical equations necessary to determine the amount of unbalance in one or two pre-selected planes using the influence coefficient method of balancing.

Maximum weight capacity 5,000 lbs.

Maximum weight capacity 5,000 lbs.

Maximum diameter over bed 63″ (1600 mm)

Maximum distance between support bearings centerlines – 68″ (1727 mm), with extended bed – unlimited.

Balancing speed 10 – 4,000 rpm

Maximum indicated sensitivity per plane (instrument readout capability) – .0001 ounce-inch / .0003 gram-inch – Dynamics Research .Com

The Dynamics Research Predictive Maintenance Model 440 takes vibration data, keeps track of all maintenance tasks, displays your measurements and prints reports in all common formats.

Takes and stores vibration FFT’s for up to 512 points on each machine

Takes and stores vibration FFT’s for up to 512 points on each machine

Printed reports on all equipment monitored.

Displays machine data as overall vibration over time, as a single FFT, or as a waterfall.

PORTABLE

This Nakamura-Tome precision turning center offers a wide range of capabilities. It is Slant 3 long bed CNC-controlled with 12″ chuck, Maximum turning diameter of 15.5″ and over 43″ between centers. This turning center has a 2.5″ bar capacity thru the spindle is ideal for processing precision shafts or can be used as a chucker manufacturing components for the aircraft, electronic and nuclear industries. Its advantages are:

Spindle speed 2500 rpm

Spindle speed 2500 rpm

25 HP motor

12-position turret

ability to quickly and easily cut through hard-to-work materials such as stainless and inconel

capability of maintaining tolerances of better than .001″

Kemsley Machinery Co., Inc.